Dal‑SOOP System Design

The design of the Dal-SOOP systems were guided by the following requirements:

- Safety of unattended operation

- Quality of seawater supply

- Certification for shipboard use

- Ease of operation and maintenance

- Anti-fouling protection

- Simplicity and modularity

- Sensor-based measurements (passive sensing)

Design of the Dal-SOOP System:

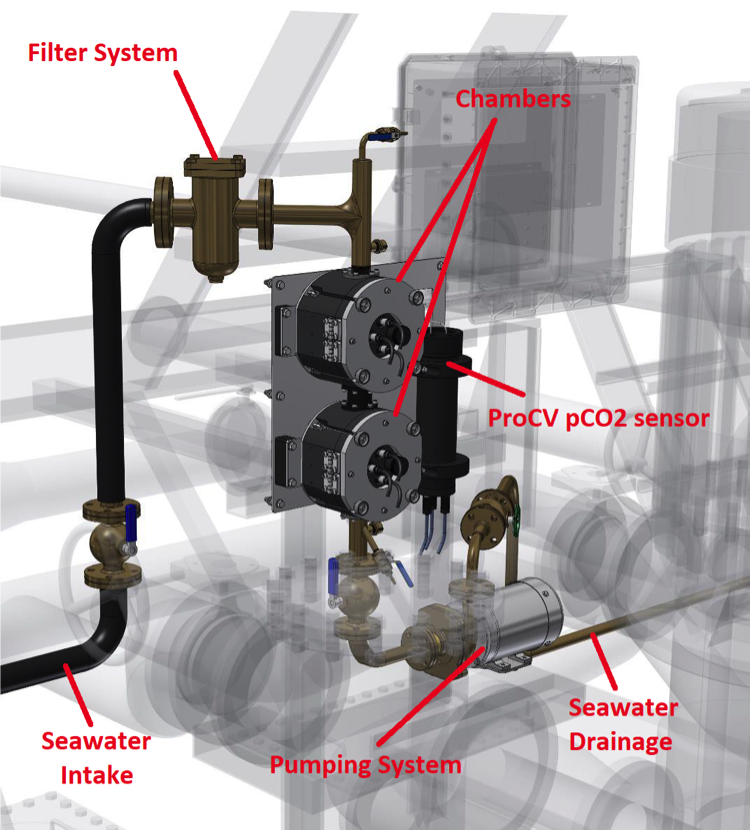

Compared to the bulky and space-demanded oceanographic sensor system, our underway system adopts a rugged and simplified approach. Two, compact in-line flow-through chambers that house multiple sensors at once are connected to the seawater intake and discharge pipes. This compact design allows easy maintenance. The sensors are then connected individually to the SMARTGUARD system in the controller box, as well as the Garmin satellite-GPS system. A filtering system (strainer) is also installed to filter the seawater supplied into the chambers.

The main sensor parameters are temperature, salinity, pressure, O2, pCO2 (CO2-Pro CV, PSI), and chlorophyll-a (Turner). Options of additional sensor installation are available. Copper-containing piping and chamber materials limits the biofouling. The use of in-situ dissolved gas sensors in place of gas analyzers increases the simplicity of the VOS design.

The underway system emphasizes the automation of the control system. The pre-programmed controller (PLC) system allows the autonomous control of flow operation while the VOS is underway or passing the geofence. The geofence is set up to turn off the water flow and data collection in selected regions where where pumped water can contaminate or damage the system and its components, mainly in the harbours. Leak detection of the PLC system will shut down the water pump if the underway system is compromised.

Data collection:

All GPS stamped data from the sensors and diagnostic data from PLC are stored internally on the SD card in the SMARTGUARD logger and can be transmitted in real-time via cellular network or iridium. Data from the SD card can also be retrieved by establishing remote communication with the SMARTGUARD through the Real-Time Data Collector (Aanderaa software) while the SOOP vessel is within the range of cell signal.

Aquatron Testing:

To ensure sensor performance and the robustness of the system, the prototype is assembled and extensively tested in the ±«Óătv University Aquatron facility which provides access to filtered seawater at a range of flow speeds and pressure from the nearby harbour.

The system design is a collaborative effort between CERC.Ocean group, , and , which ensures that both scientific and operational requirements are met. The development of the system is also supported by .

Dal-SOOP system mechanical design with labels