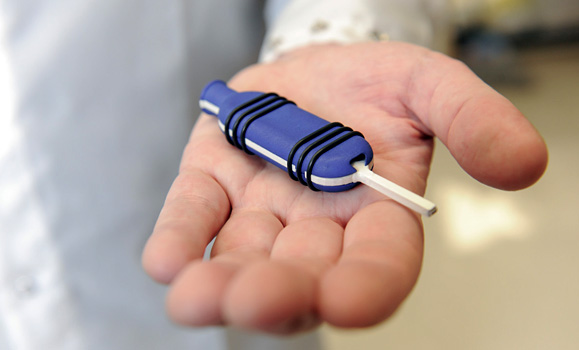

It looks like a key, the sort youâd find in some high-tech fancy new car. Its casing is round and plastic, its blade long, thin and metallic.

At the tip, inside of a square thatâs only a few millimetres across, are somewhere between 64 and 128 miniature ultrasound receivers. And itâs these tiny receivers that will allow doctors to explore the inside of the human ear with greater precision than ever before.

The technology, developed by the team of researchers at ±«Óătv and Capital Health, is the worldâs first high-resolution, endoscopic ultrasound-imaging probe. Itâs poised to offer ear clinicians a tool theyâve never had before: a way to diagnose issues of the inner and middle ear without surgery.

On Tuesday, Colibri Technologies, an Ontario-based health-care technology company, together with ±«Óătv and Capital Health, announced it is licensing the technology and plans to begin manufacturing the new probe in its Toronto facilities.

Small device, big opportunity

The probe represents another exciting invention from an incredibly successful partnership of three researchers: Jeremy Brown, Rob Adamson and Manohar Bance. Though there are a number of cross-appointments between them, Drs. Brown and Adamson are largely based in Biomedical Engineering, whereas Dr. Bance is a clinician/researcher in the Faculty of Medicineâs Division of Otolaryngology.

âAll our technologies are centred around the auditory system, and thatâs because of our close collaboration with Dr. Bance,â explains Dr. Brown, lead developer for the ultrasound-imaging probe.

âJust having access to a clinician like that, so we can learn about prospective pathologies we can diagnose, or where to implant hearing aids â as scientists and engineers, weâd have no clue. So having a clinician, you get that perspective.â

Their team, part of the S.E.N.S.E. Lab (Sensory Encoding and Neuro-Sensory Engineering), holds more than a dozen patents and co-owns several companies. Its latest creation, the ear probe, is an extension of Dr. Brownâs research into high-resolution ultrasound imaging, an expertise heâs been developing dating back to his own PhD studies.

âThe first thing I said when I started collaborating with Dr. Bance on some of the hearing aid technologies was, âHow do you image the ear?â And he responded simply: âWe donât.â CT scans and MRIs are too low a resolution, and nothing else can gain access to the ear because itâs not optically transparent.â

The new device allows clinicians to explore the inner ear without surgery, and to peer inside the middle ear at resolutions 10 times clearer than the status quo. This can help diagnose a number of concerns inside the ear, with examples ranging from a malfunctioning implant device through to MĂ©niĂšre's disease.

The challenge in developing a probe like this? Size: traditionally, an ultrasound probe is often several centimetres across, way too large to work inside the ear.

âTo miniaturize it into something small enough, you really have to cheat a lot, basically,â explains Dr. Brown. âYou can do that through microfabrication technologies and also signal processing technologies â and here, weâve done both.â

Hands-on opportunities for students

Helping take the probe from concept to reality is the labâs team of 12 researchers and engineers, several of whom are graduate students or postdocs at Dal.

Biomedical Engineering PhD student Andre Bezanson has been helping to build the device. âWeâve been using these techniques that are the same for shrinking down the microchips in cell phones to get similar cell reductions,â he explains. âSo Iâve been doing a lot of that hands-on work.â

Bezanson says the opportunity to work on a project such as this has been invaluable for his career.

âItâs one of those applications where thereâs not a lot of people trained in it, but thereâs such a high demand for the skill set. Weâre at the leading edge of being able to make things smaller.â

âIf you were to ask me what my primary objective is, itâs training students and postdocs and research engineers,â says Dr. Brown. âThe experience theyâre getting here is training in a lab that is among the top in the world at developing this technology, and they also get hands-on experience for all of the same processes used in the semiconductor industry. They graduate with a really valuable training in next-generation technologies.â

Kate Latham is a masterâs student in the lab, currently working on translating elements of the imaging system from digital to analog.

âThe lab is great,â she says. âJust look around: thereâs so many exciting things we get to work on. Since working in the lab, Iâve decided to switch to a PhD program, and that was never in the plan originally.â

As for the ear probe, the team plans to continue to refine the technology, improving the image quality, while Colibri begins working to bring the product to market. The team also expects to begin pre-market clinical studies within the next six months.

The probe has been developed through a $3.8 million Capital Health-led research and development project, with an investment of $2.6 million from the Atlantic Canada Opportunities Agencyâs Atlantic Innovation Fund. Other funders include NSERC, Canadian Institutes of Health Research, Innovacorp, Capital Health and ±«Óătv.