Clean and NextGen Materials

A more sustainable future requires the development of products with improved performance, productivity and efficiency while at the same time reducing costs, energy consumption and waste. Meeting that goal requires research in advanced manufacturing, advanced materials, andÌývalorization and the extraction of resources from what was previously considered waste.

ADVANCED MANUFACTURING

Reducing the weight of components in the transportation sector is one part of the strategy to reduce greenhouse gas emissions associated with the transportation sector. When lightweight structures are manufactured using technologies that are efficient in both energy and material usage, the carbon footprint is even further reduced.

POWDER METALLURGY

,ÌýKevin PlucknettÌý²¹²Ô»åÌýÌýare developing innovations in the area of powder metallurgy (PM) processing of innovative products for the aerospace and automotive sectors.Ìý’s research pertains to the conversion of metallic powders into engineered components for a range of industrial sectors. His activities in PM stress the development and commercialization of robust industrial processing practices, hot forging of aluminum PM alloys, advanced mechanical property testing of PM alloys, and titanium PM.ÌýÌýis currently the NSERC/Pratt and Whitney Canada Industrial Research Chair in Structural Brazing and Processing of PM Superalloys. His work is primarily in the areas of metal injection molding PM and joining of light metals (e.g. Al and Ti) and Ni based superalloys for aerospace and automotive applications. He specializes in the application of high temperature thermal analyses, including differential scanning calorimetry (DSC), Laser Flash Thermal Diffusivity (LFTD), combined DSC/Thermogravimetry(TG)/gas chromatography-mass spectrometry(GC-MS) and dilatometry, to various PM and brazing operations. Together, sintering and brazing represent net shape, manufacturing methods that reduce costs, energy usage and materials waste, making them sustainable manufacturing methods.ÌýKevin Plucknett'sÌýPM research currently the effects of water jet peening on PM products made from titanium and aluminum alloys.

ADDITIVE MANUFACTURING

Ìýis developing additive manufacturing (AM) processing strategies designed to accommodate a range of material systems that include light metal alloys based on aluminum and titanium, high durability metal/ceramic composites, and advanced high strength steels. Core AM technologies of interest include laser powder bed fusion, directed energy (laser) deposition, and binder jet printing. ÌýHis work also emphasizes the use of powder fed laser deposition as a means to repair worn components and for the free-form fabrication of prototypes.ÌýÌýAli Nasiri is currently a Canada Research Chair working on the fabrication of large structural components by means of wire-fed AM technology.Ìý He also studies the processing of aluminum alloys in the context of laser powder bed fusion.ÌýKevin Plucknett's research on AM emphasizes the design and development of functional gradient materials.Ìý Core materials of interest include tool steels and cermet material systems.ÌýYunyun Wu is developing machine embroidery-based AM processes for the fabrication of electronic textile devices and eco/bioresorbable electronics.

ADVANCED MATERIALS

COATINGS

Kevin PlucknettÌýis developing high performance ceramic-metal composites and coatings, boride-based coatings on titanium and iron alloys.

SUPERALLOYS

Ìýis developing Ni-based superalloys for aerospace and automotive applications, with particular interest in optimizing existing manufacturing methods and understanding processing-microstructure-property relationships.

CERAMICS AND CERMETS

Kevin Plucknett’s research focuses on high performance ceramic-metal composites and coatings. He has also worked withÌýBrian LilleyÌýtoÌýinvestigate novel ceramic material and production techniques andÌýin situÌýenvironmental interactions, beneficial to microclimate systems.

POLYMERS

Alison Scott designs polymeric materials for target applications by investigating links between polymerization synthesis conditions (and polymerization kinetics), polymer structure, polymer properties, and industry-specific application requirements. A statistically informed design approach ensures the best use of available resources during material development (avoiding trial-and-error techniques) and leads to improved application performance.

COMPOSITES

Ìýworks on a novel 3D-fiber metal laminate composite (3D-FML), which is both lightweight and resilient, offering significant stiffness, strength and impact resistance that is more cost-effective when compared to the conventional fiber-reinforced polymer composite (FRP).ÌýÌýCurrent efforts are in progress to develop a new generation of the 3D-FML that will be eco-friendly, sustainable, and cost-effective.ÌýÌýA new rendition of the 3D-FML is also being developed by hybridization of the 3D-FML with graphene nanoparticles (GNP) and the hybrid composite is being optimized computationally.ÌýÌýHis group is also testing a unique thermoplastic resin in conjunction with the new 3D-FML.ÌýPedram SadeghianÌýis exploring innovative and sustainable solutions that can be applied to different features of civil engineering infrastructure. His team uses advanced materials such as fiber-reinforced polymer (FRP) composites and innovative technologies to upgrade existing infrastructure and build new ones with longer life span, less environmental footprint, and better service.ÌýKevin PlucknettÌýis developing high performance ceramic-metal composites.

GLASS

Ìýis interested in the development of new glassy materials for application in optical instruments and construction, using a combination of experimental, computational, and theoretical approaches to understand glass structure and environmental response.

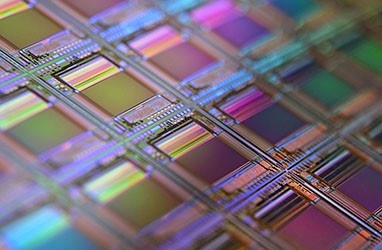

ELECTRONIC MATERIALS

Ìýinvestigates theÌýproperties of colloidal quantum dots and carbon nanotubes to develop their potential in the next generation of electronics, including new light-absorbing solar cells and electronic textiles.ÌýÌýstudies and develops organic electronic materials and devices (OLEDs), with a particular interest in Organic Thin Film Transistors and organic-based solar cells.ÌýÌýis focusing on the development of new conducting polymers and novel synthetic approaches to facilitate the use of conducting polymers in emerging technologies.Ìý’s research interests lie in the preparation of nano- and micro-materials using solid-state reactions. Her group is working on the development of low-cost ceramic plasmonic nanostructures with applications in desalination, water treatment, disinfection, and sensing purposes.ÌýÌýapplies ultrafast optical techniques to the study of rapid processes in semiconductor materials of interest for a variety of applications, including solar cells, photonic and spintronic devices, and next generation computing technologies that would exploit quantum mechanical effects. Yunyun Wu is focusing on developing fiber-shaped eco/bioresorbable electronic materials for fabricating electronic devices which can degrade in the environment or be resorbed by the human body.

BIOMATERIALS

ÌýinvestigatesÌýthe design rules underlying the unique mechanical properties of protein assemblies, cells and tissues, studying the relationship between structure and mechanical properties for peptides and proteins assemblies.ÌýKevin Plucknett‘s research interests in advanced engineering materials includes polysaccharide and protein biopolymers, with particular interest in processing-microstructure-property relationships.ÌýÌýworks on the use of nanoparticles in a variety of applications, including orthopedic implants, as chemical scaffolds to regulate the enzymatic activity and in protein separation, with potential for other applications such as drug delivery, MRI contrast agents and hyperthermia therapy.

NANOTECHNOLOGY

‘s research is intended to improve the ability to precisely control the structure and properties of multi-component nanoparticles by developing efficient synthetic methodology and exploring the applications of these nanoparticles in catalysis, energy and biomedicine.ÌýÌýis working on developing inexpensive ceramic plasmonic nanostructures primarily composed of transition metal nitrides and carbides for applications in desalination, water treatment, disinfection, and sensing purposes.ÌýHer research also includes engineering photocatalyst nanoparticles to enhance carrier collection and improve the overall efficiency of the chemical reaction.ÌýÌýinvestigates nanomagnetic materials, growing nanolayers of chiral magnets by molecular beam epitaxy and exploring the influence of strain and nanoscale size on the magnetic structure.ÌýÌýinvestigates nanomaterials to develop their light absorbing materials, next generation electronics sensors and electronic textiles.

Ìý

WASTE TO RESOURCE

Waste utilization and treatment are among the research interests ofÌýSu-Ling BrooksÌý²¹²Ô»åÌýQuan Sophia HeÌýwith the development of biofuels and biochemicals from biowaste andÌýnon-conventional crops a particular focus. Su-Ling BrooksÌý and her team have had recent projects in the recovery of high-value compounds (e.g. bioactives, enzymes, nutraceuticals) from process wastes and the conversion of process wastes into higher-value products (e.g. oils, fermentation products).

Quan Sophia HeÌý²¹²Ô»åÌýAzadeh Kermanshahi-pourÌýstudy anaerobic digestionÌýand the potential uses for the by-products of that process. Focussing on reaction engineering and separation engineering,ÌýQuan Sophia HeÌýworks on the development of biofuels and biochemicals from non-conventional crops and biowaste, novelÌý nanocatalyst development and applications and the separation of chiral drugs and chiral pesticides.ÌýAzadeh Kermanshahi-pour's research is centered on derivation of bioenergy and value-added chemicals from renewable resources within an integrated biorefinery.Ìý Her focus area extends to the development of green extraction processesÌýusingÌýsupercritical fluids, as well as anaerobic digestion, bioremediation, identification of biodegradation pathway of chemicals in the environment and the treatment/reuse of effluent streams from industrial sources.